ARCOSYSS

THE BEST BUILDING CONSTRUCTION TECHNOLOGY

Rapid | Rigid | Resilient

ARCOSYSS

A COMPOSITE CONSTRUCTION TECHNOLOGY

Stronger than RCC | Stiffer than STEEL | Faster than PREFAB

ARCOSYSS

A SYNERGY OF 3 PROVEN TECHNOLOGIES

RCC + STEEL + PREFAB

ARCOSYSS : Genesis

Modern building construction adopts 3 proven construction technologies such as RCC, STELL & PREFAB.

However, each of these technologies has its own advantages and disadvantages.

RCC structures are strong, sturdy & durable but they are bulky, labour intensive and not ductile.

STEEL structures are sleek, ductile & have high strength to weight ratio but they are costly,

have a tendency to buckle & are prone to corrosion.

PREFAB structures are quality proof, sustainable and cost-effective but they are equipment

intensive, prone to leakages at joints and need considerable lead time.

What happens when we INNOVATE & BLEND these 3 proven construction technologies?

It results in a SYNERGY called ARCOSYSS TECHNOLOGY - a composite construction technology that combines the advantages of the 3 proven construction technologies such as RCC, STEEL & PREFAB.

It results in a SYNERGY called ARCOSYSS TECHNOLOGY – a composite construction technology that combines the advantages of the 3 proven construction technologies such as RCC, STEEL & PREFAB.

ARCOSYSS: Definition & Algorithm

ARCOSYSS is an acronym for ARmoured COncrete SYnergy Structural System

ARCOSYSS is a trailblazing & scientifically validated composite construction technology that combines the advantages of 3 proven construction technologies: RCC, STEEL & PREFAB.

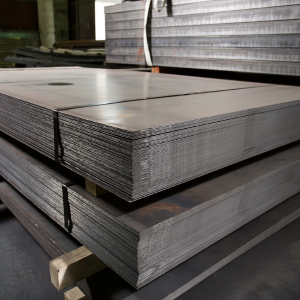

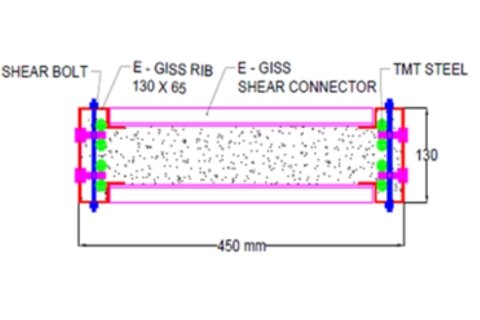

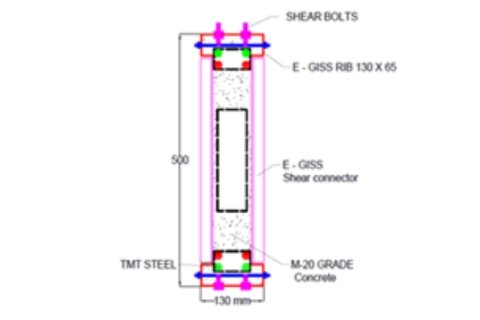

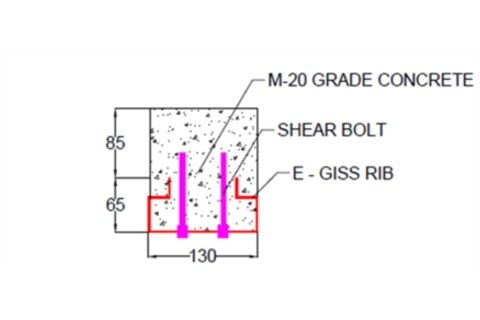

Arcosyss uses 4 time-tested construction materials: GI Structural Steel, TMT Steel, Cement & Aggregates to manufacture 5 Unique Arcosyss structural elements and 6 Unique Arcosyss structural components.

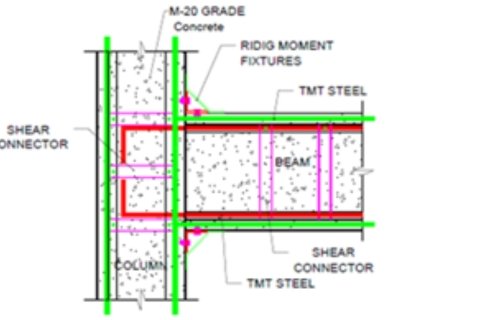

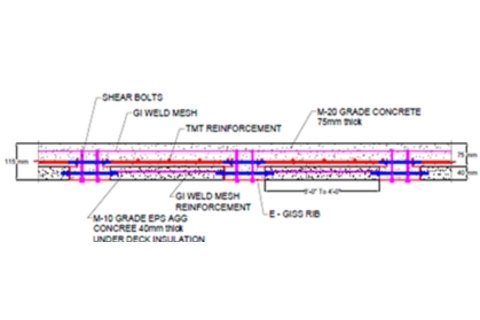

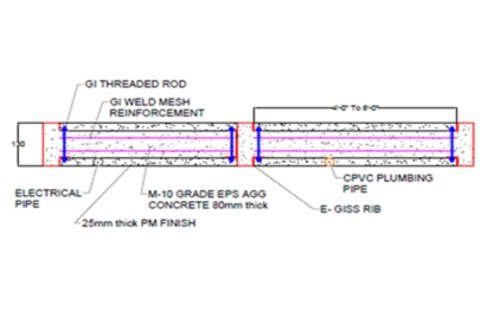

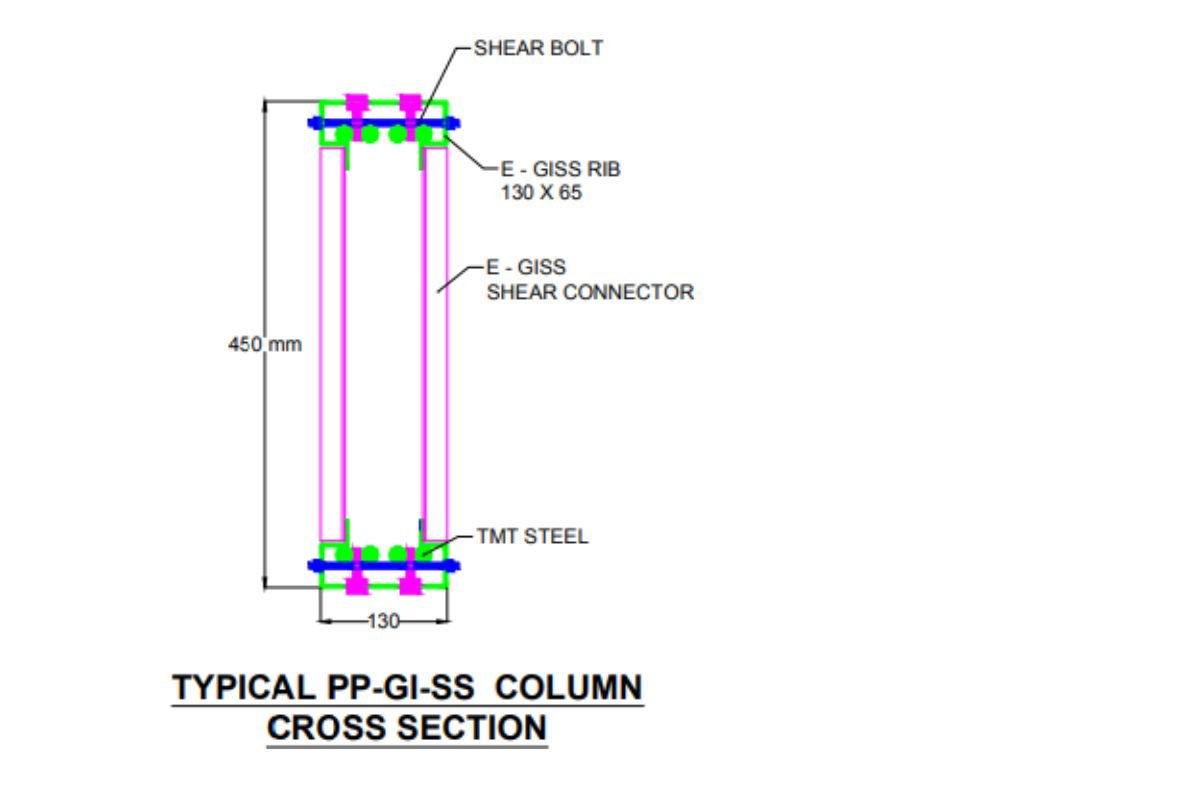

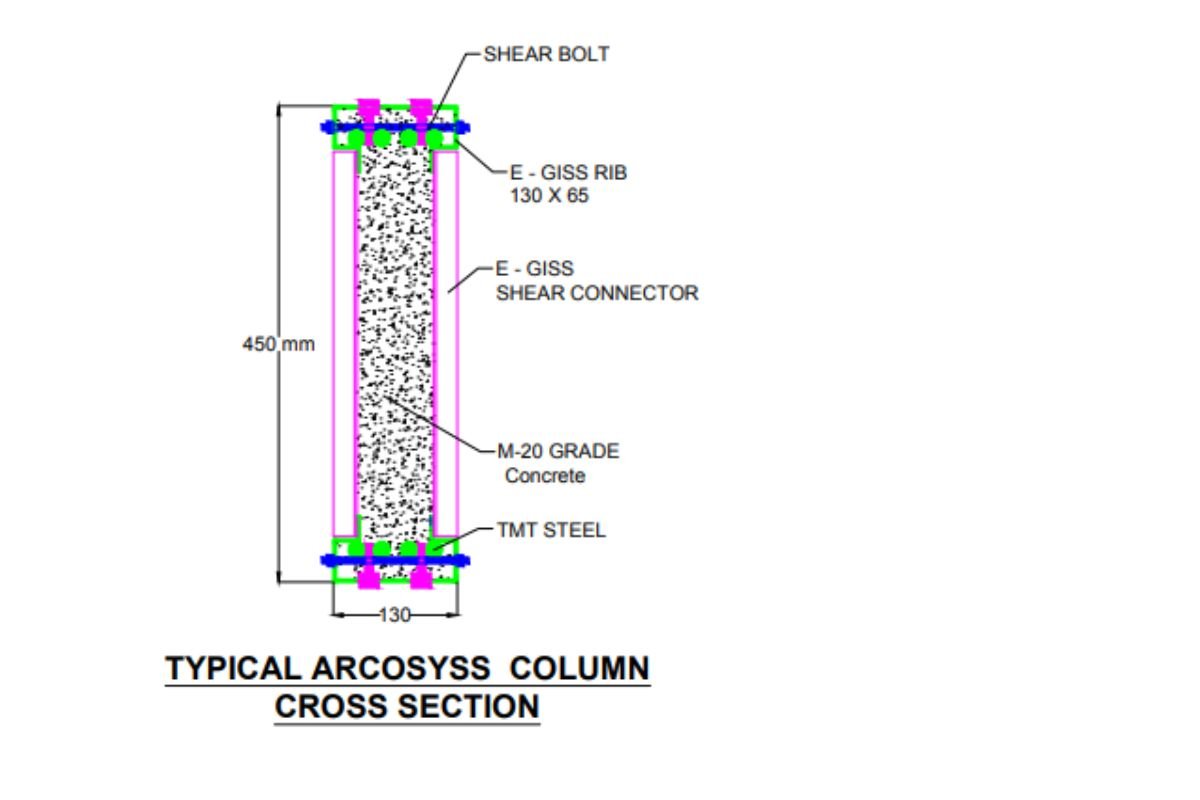

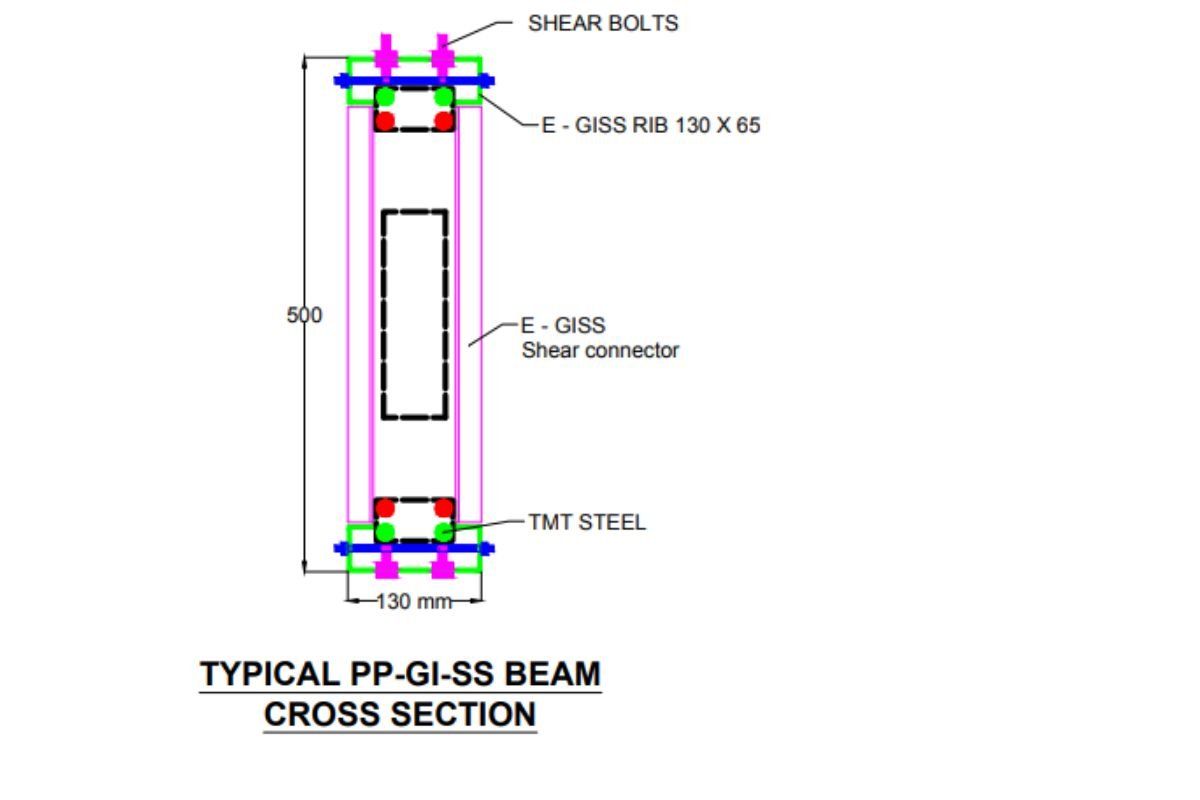

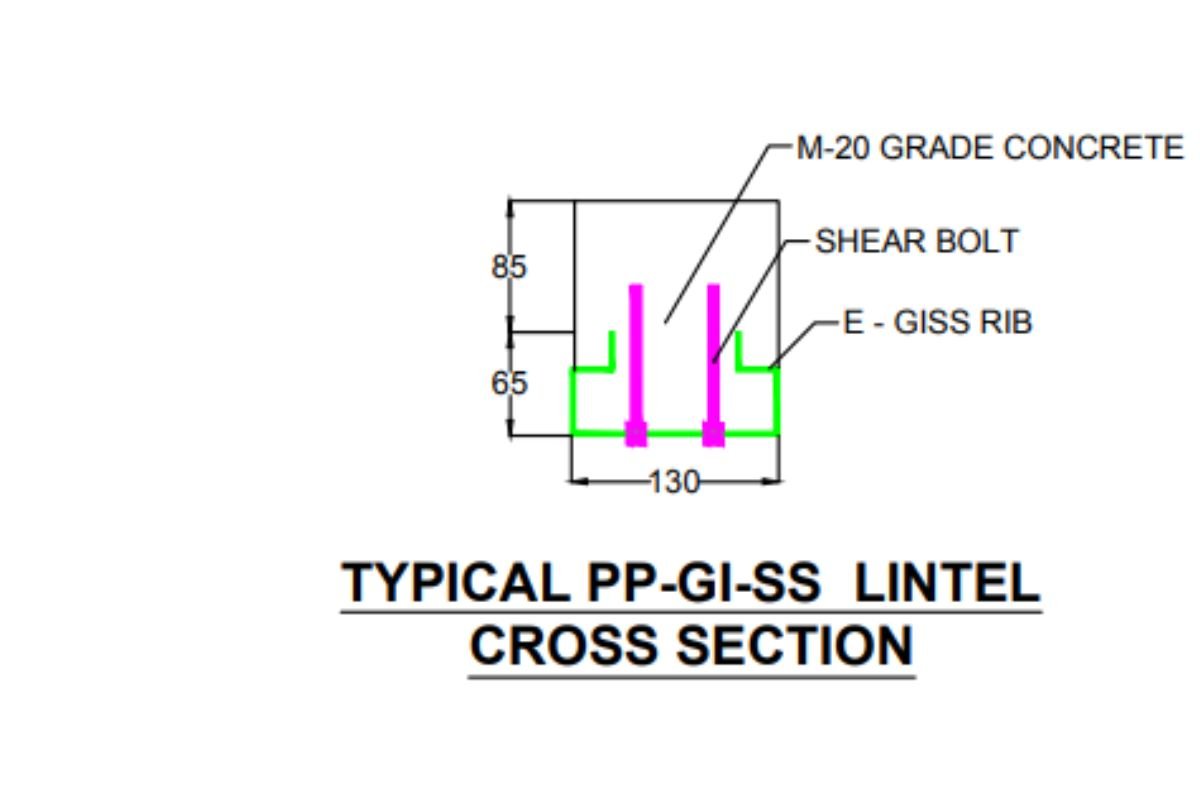

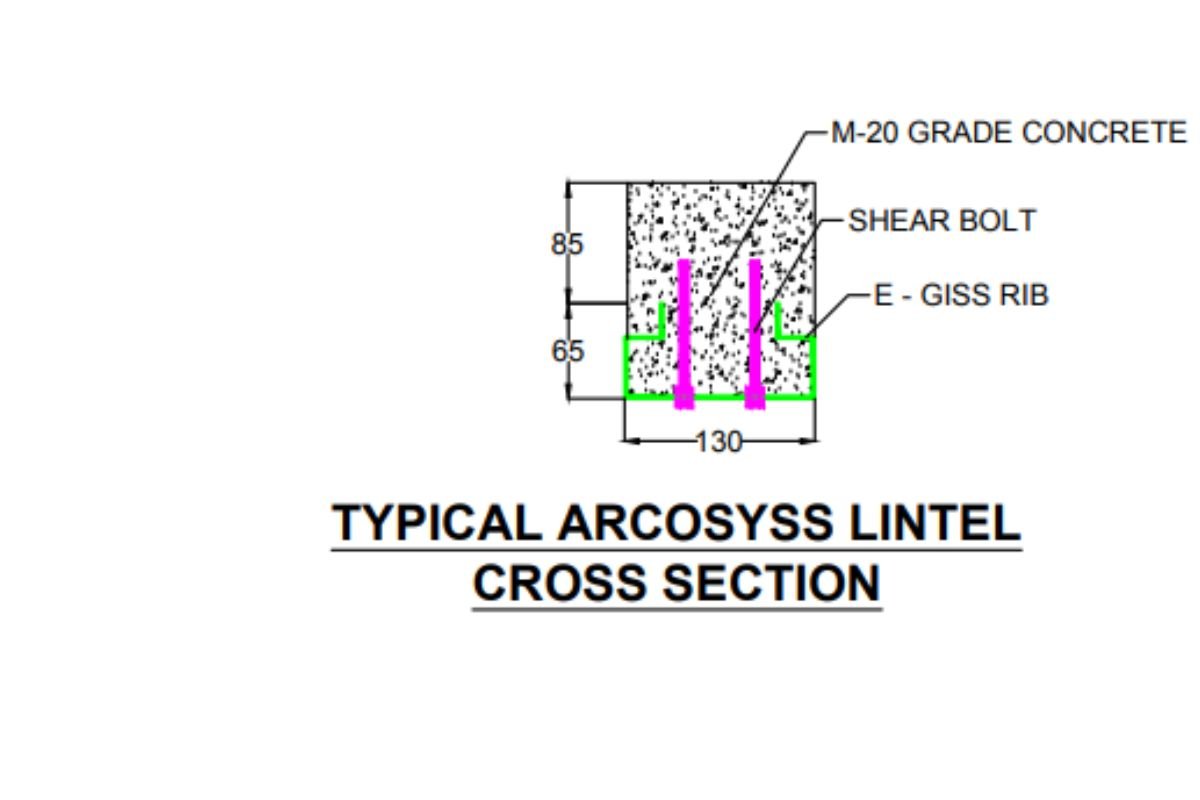

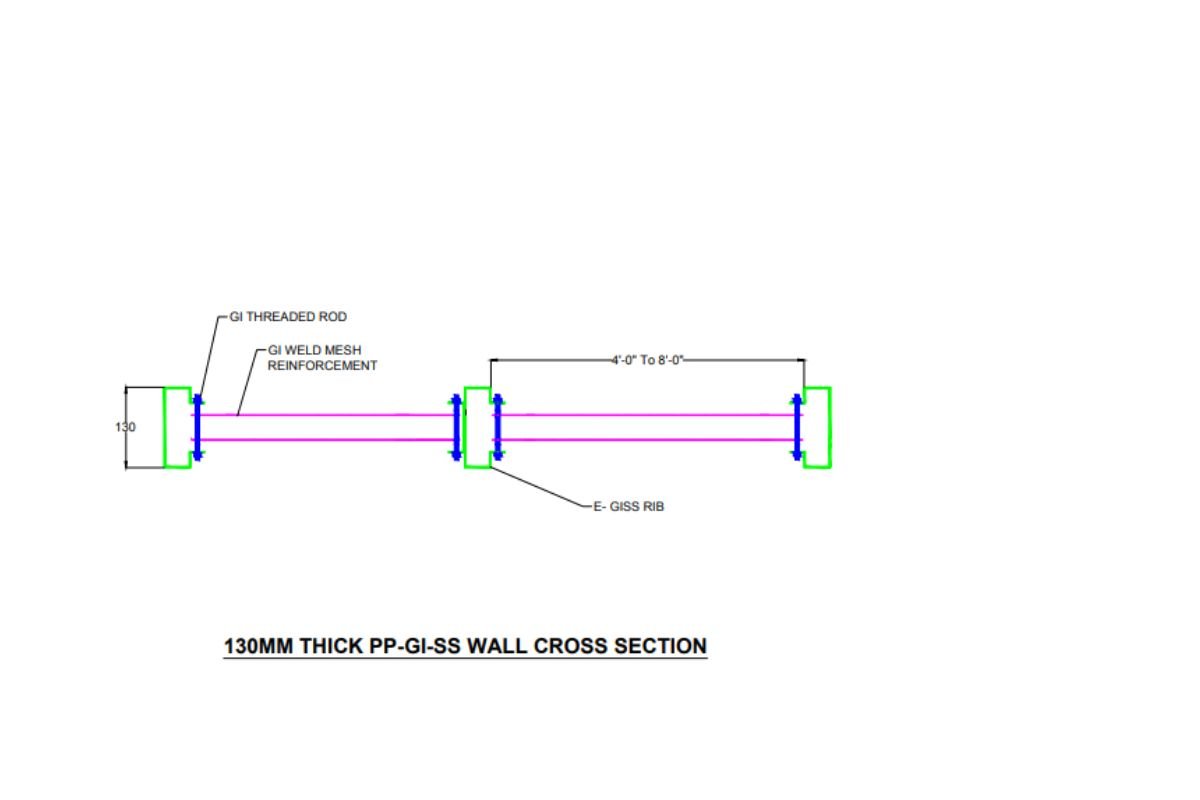

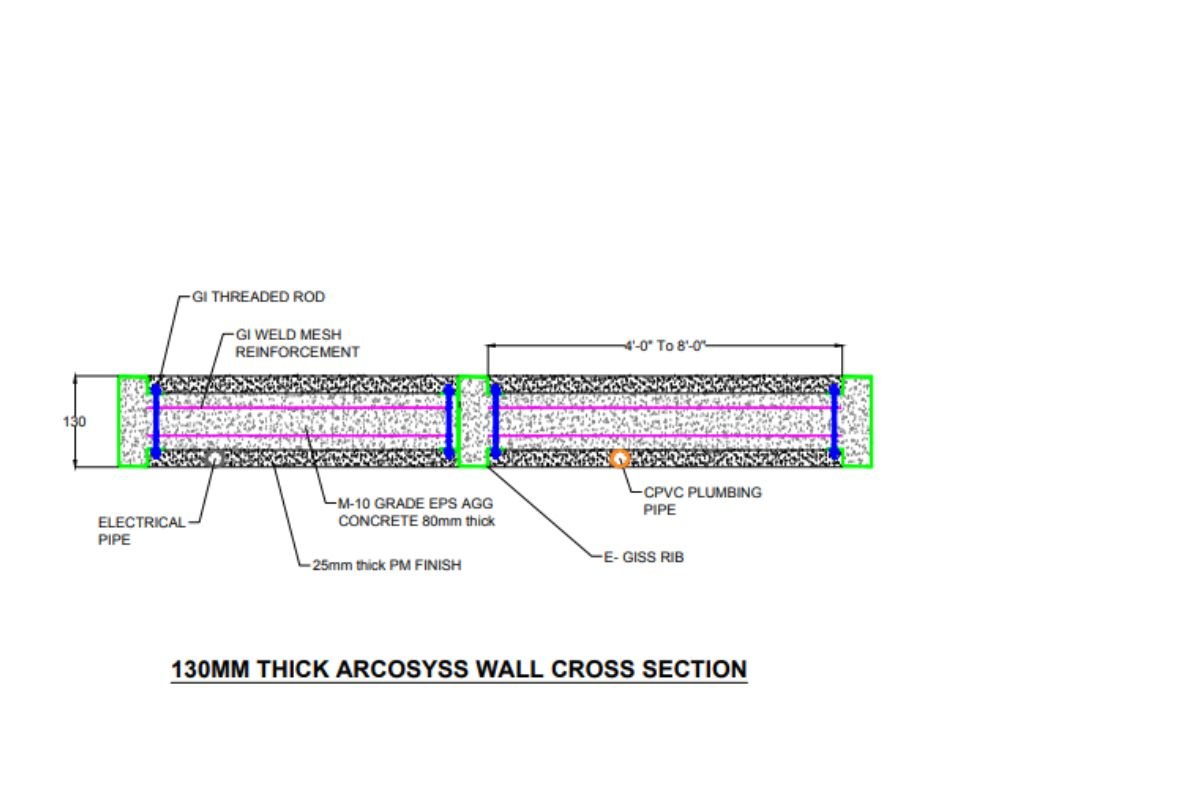

The 5 Unique Arcosyss Structural Elements are : E-GISS Rib, E-GISS Shear Connector, E-GISS Rigid Moment Fixture, PM Concrete & PM Mortar

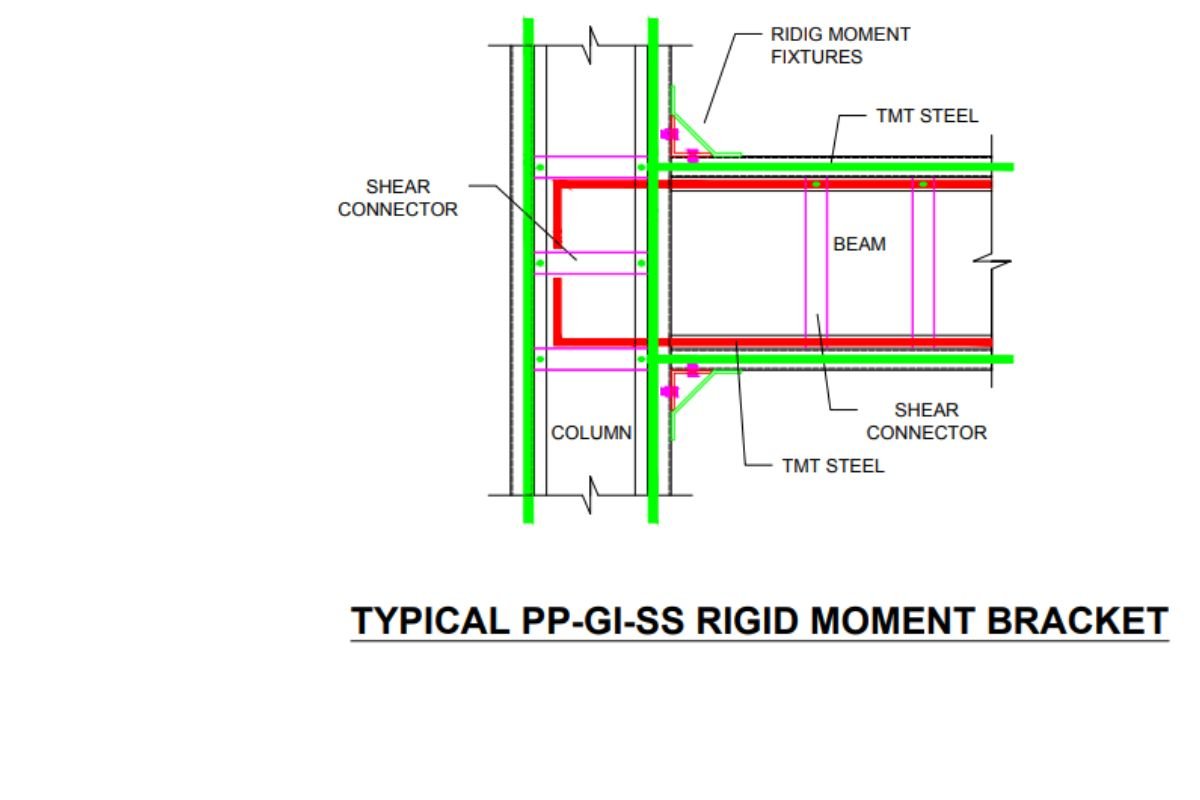

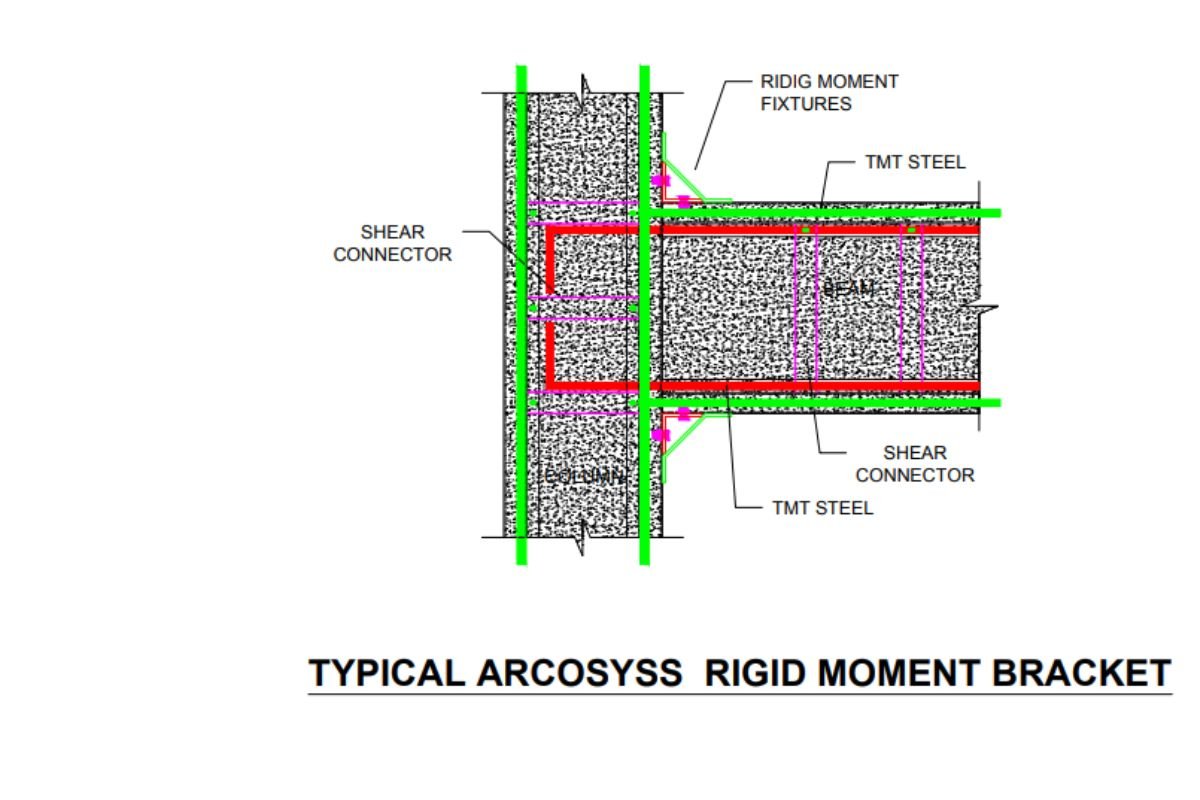

The 6 Unique Arcosyss Structural Components are : Arcosyss Column, Arcosyss Beam, Arcosyss Lintel, Arcosyss Rigid moment bracket, Arcosyss Slab & Arcosyss Wall

GISS is an abbreviation for Galvanised Iron Structural Steel

ARCOSYSS: 3 – 4 – 5 - 6

INNOVATE & BLEND 3 Proven Technologies:

RCC Technology

STEEL Technology

PREFAB Technology

Aggregates

PM Mortar

- RCC Technology

- STEEL Technology

- PREFAB Technology

USE 4 Time-tested Construction Materials:

- Galvanised Iron Structural Steel

- TMT Steel

- Cement

- Aggregates

Galvanised Iron Structural Steel

TMT Steel

Cement

Aggregates

PM Mortar

ARCOSYSS : Structural Elements ( Six Elements )

PRODUCE 5 Unique Structural Elements:

E-GISS Rib

E-GISS Shear Connector

E-GISS Rigid Moment Fixture

PM Concrete

PM Mortar

ARCOSYSS : Structural Components

MANUFACTURE 6 Unique Structural Components:

Arcosyss Column

Arcosyss Beam

Arcosyss Lintel

Arcosyss Rigid Moment Bracket

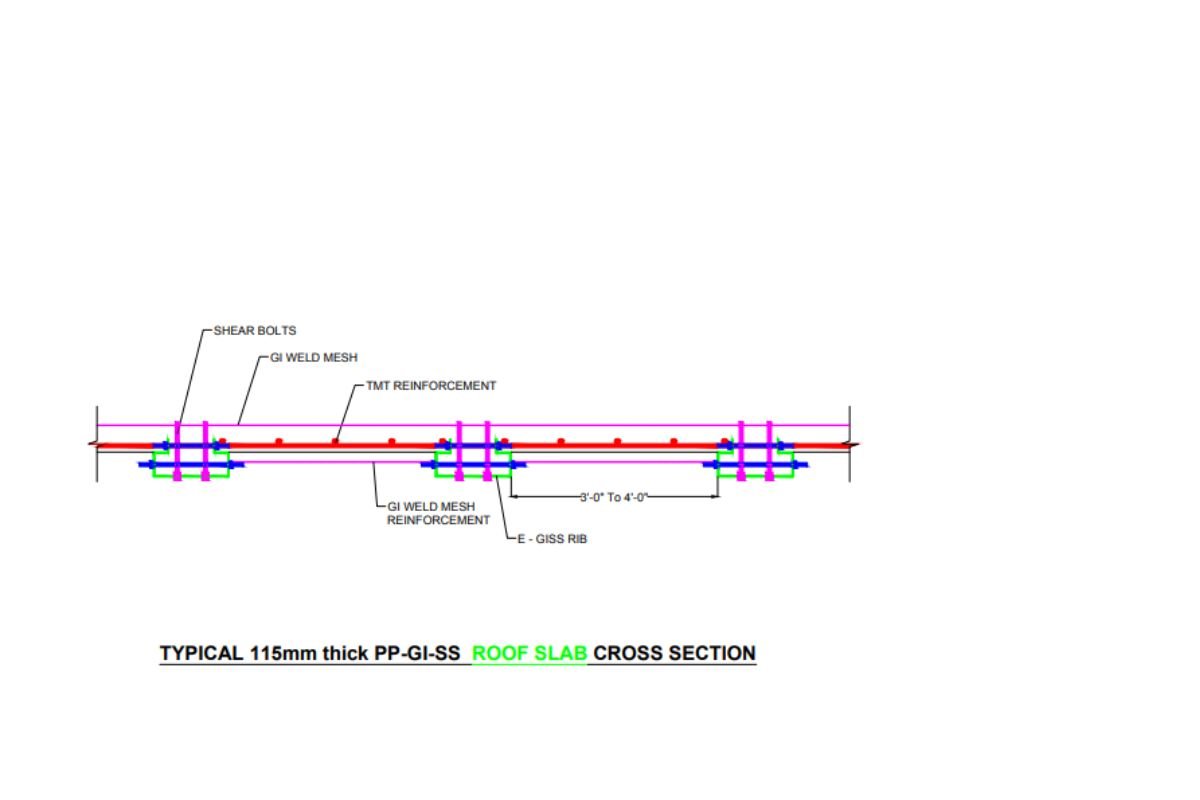

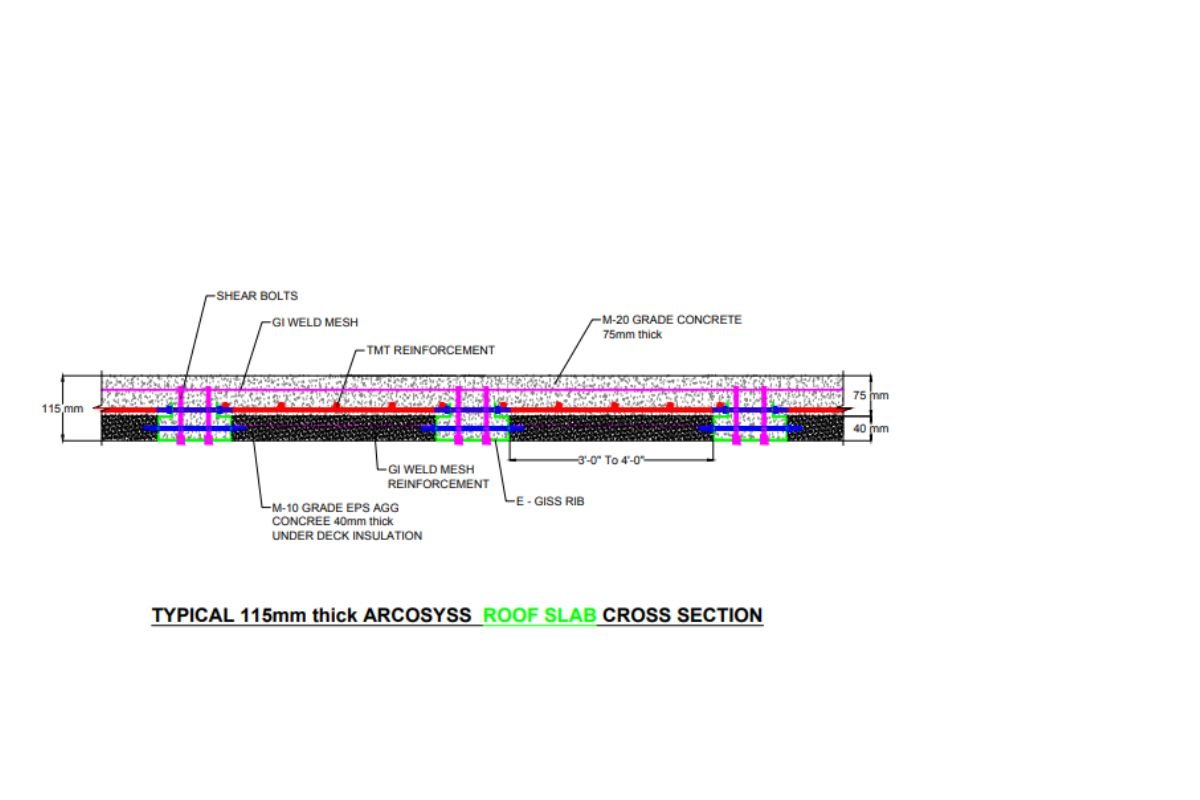

Arcosyss Slab

Arcosyss Wall

INSTALL these components into any structural form to get a building of your choice based on Arcosyss construction technology

ARCOSYSS Technology

ARCOSYSS

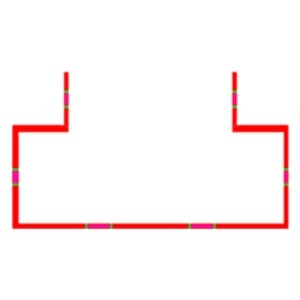

Structural Transformation - Column & Beam

ARCOSYSS

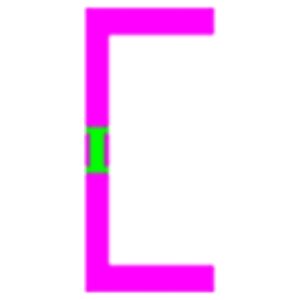

Structural Transformation - Lintel & Rigid Moment Bracket

ARCOSYSS

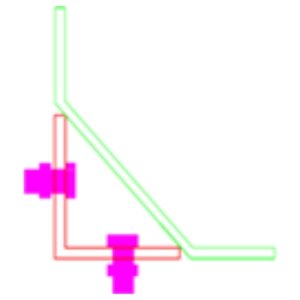

Structural Transformation - Wall & Slab

ARCOSYSS: Building Attributes ( E-SMART)

Buildings built by adopting ARCOSYSS construction technology exhibit certain unique attributes: E-SMART

- E – Eco-friendly & Economical

- S – Strong & Sustainable

- M – Modern & Modular

- A– Aesthetic & Affordable

- R– Reliable & Rapid

- T– Thermally Temperate

ARCOSYSS: Construction Protocol

The implementation of ARCOSYSS Building Construction Projects are carried out by trained and authorised associates of The CE-Mentor.

ARCOSYSS structural components are exclusively manufactured and supplied by Sansucrete Construction Products LLP – a manufacturing associate of The CE-Mentor

-

ARCOSYSS Building Construction Protocol Involves

Six Important Steps:

1.Modelling, Analysis & Design of the structural configuration

2.Value engineering & BOQ preparation of the structural configuration

3.Off-site Production of The UNIQUE Arcosyss structural elements & components as per the structural configuration

4.On-site integration of structural components as per the structural configuration

5.On-site concreting of structural components using PM Concrete

6.On-site finishing of structural components using PM Mortar

7.The UNIQUE Arcosyss structural elements & components are exclusively manufactured and supplied by SANSUCRETE construction products LLP

ARCOSYSS:

Concept, Invention, Research, Innovation & Development

Innovation & Development

ARCOSYSS is a trailblazing, scientifically validated, composite construction technology; conceptualised, invented, researched, innovated & developed by Sebastian Gomes. He is the founder of The CE-Mentor and has 40 years of experience in research, innovation, development & implementation of various innovative building construction technologies.

Sebastian Gomes along with his co-founder Christopher Wilson Fernandes has built more than ONE LAKH SFT of buildings based on Arcosyss construction technology in Bangalore & Salem, over the last 5 years.

The UNIQUE Arcosyss structural elements & components are exclusively manufactured and supplied by SANSUCRETE construction products LLP – a company promoted by Sebastian Gomes, Christopher Wilson Fernades & Isaac Joseph Edwards.

ARCOSYSS Advantages (Synergy Benefits)

1.ARCOSYSS structures are Stronger, Stable & Sturdier than RCC structures

2.ARCOSYSS structures are Sleeker, Stiffer & ductile than STEEL structures.

3.ARCOSYSS structures are Light, Modular & Rapid than PREFAB structures.

4.ARCOSYSS structures Yield Savings in labour, materials, equipment, cost, time, space, energy & water.

5.ARCOSYSS structures Add Value with regard to, EQ- resistance, Serviceability, Sustainability & Scalability.

ARCOSYSS: Applications

ARCOSYSS composite construction technology can be adopted to meet each and every construction need. Accordingly it can be effectively adopted in the construction of the following type of buildings

- Residential Buildings

- Commercial Buildings

- Institutional Buildings

- Industrial Buildings

- Factory Buildings

- Mass Housing & Ware Housing

- Construction of all types of infrastructure related to buildings such as OHT, Underground Sump, Compound wall and STP Structures

ARCOSYSS : Efficacy

Buildings built by adopting Arcosyss construction technology are more effective than buildings built by adopting conventional construction technologies namely RCC, STEEL & PREFAB

Cost effective

Delivers value added structures at no additional cost.

Time effective

Enables rapid construction; due to the reduction in lead time and form work time; without compromising on quality or structural integrity.

Space effective

Provides enhanced carpet area due to sleekness of the structural form without compromising on quality or structural integrity.

Skill effective

Freedom from several skills due to simplified construction processes, without compromising on quality or structural integrity.

Service effective

Meets serviceability criteria better than conventional systems due to composite construction.

Strength effective

Provides enhanced strength due to synergy between RCC & STEEL technologies

Quake effective

Ensures better safety against seismic activity due to enhanced resilience

Weight effective

The sleek structural configuration without compromising on quality or structural integrity ensures lesser self weight.

ARCOSYSS BUILDINGS : Comparison with Steel & RCC Buildings

| S.No | PARAMETERS | BUILDINGS BASED ON STEEL TECHNOLOGY | BUILDINGS BASED ON RCC TECHNOLOGY | BUILDINGS BASED ON ARCOSYSS TECHNOLOGY |

|---|---|---|---|---|

| 1 | Strength To Weight Ratio | High | Low | High |

| 2 | Speed Of Implementation | Medium | Medium | Rapid |

| 3 | Cost Per SFT Of Construction | Costly | Affordable | Affordable |

| 4 | Steel Consumption | 6 To 8 Kgs/ Sft | 3.5 Το 4.5 Kgs/Sft | 2.5 To 3.5 Kgs/ Sft |

| 5 | Concrete Consumption | Less | More | Moderate |

| 6 | Skilled Labour Input | More | Less | Less |

| 7 | Passive Fire Resistance | 2 Hours | 2 Hours | 2 Hours |

| 8 | Corrosion Resistance | Good | Good | Very Good |

| 9 | FR Paint Treatment | Very Expensive | None | Less Expensive |

| 10 | Corrosion Paint Treatment | Expensive | None | None |

| 11 | Labour & Material Input | High | High | Less |

| 12 | Ductility & EQ Resistance | Good | Satisfactory | Very Good |

| 13 | Durability | Good | Good | Good |

| 14 | Supervisory Input | High | Regular | Regular |

| 15 | Suitability For High Rise Buildings | Highly Suitable | Highly Suitable | Highly Suitable |

| 16 | Material Handling | Needs Heavy Equipment | Needs Heavy Equipment | Needs Light Equipment |

| 17 | Salvage Value | More | More | Less |

| 18 | Form Work | Less | More | Less |

| 19 | Value Addition | Average | Average | Very Good |

| 20 | Software For Analysis & Design | STAAD / ETABS | STAAD / ETABS | STAAD / ETABS |

Projects Completed based on ARCOSYSS Construction Technology

More than ONE LAKH SFT of buildings have been built in Bangalore and Salem over the last 5 years based on Arcosyss Construction Technology. The list of BUILDINGS completed / under construction is shared below.

15000 sft of Long-span High-bay club house structure in Bangalore

25000 sft of Long-span High-bay industrial structure in Bangalore

10000 sft of Long-span school building structure in Bangalore

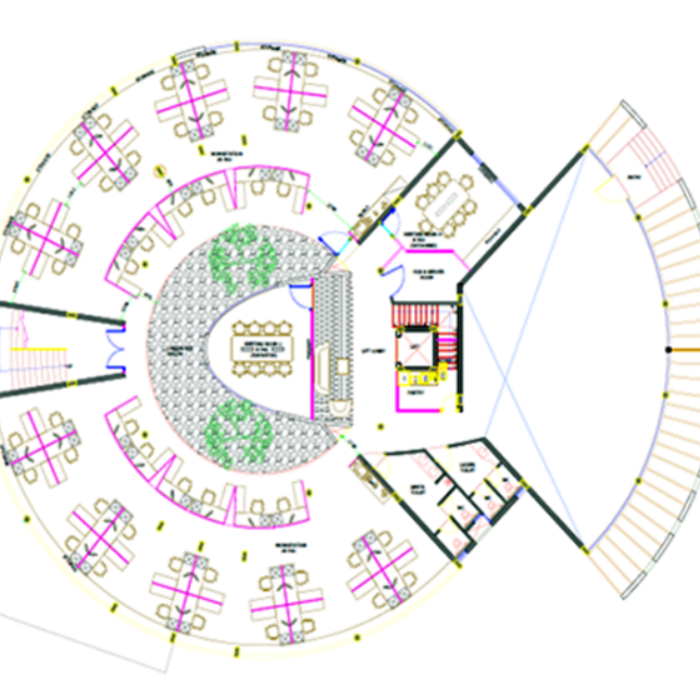

10000 sft of Long-span IT facility structure in Bangalore

10000 sft of Long-span hospital building structure in Bangalore

20000 sft of Long-span industrial building structure in Salem

15000 sft of apartment building structure in Bangalore

20000 sft of apartment building structure in Salem

2000 sft of residential house structure in Bangalore

3000 sft of Long-span High-bay structure for an IT facility in Bangalore

5000 sft of villa building structure in Bangalore

10000 sft of apartment building structure in Bangalore

Club House at – Bangalore : ARCOSYSS BUILDING - HIGH-BAY framed structure 40 feet clear span : 15000 SFT total built up area

Ware House /Multi-purpose Hall at Salem : ARCOSYSS BUILDING 100 feet clear span : 20000 SFT total built up area

Villa project in Bangalore: ARCOSYSS BUILDING: low rise framed structure 5000 sft total built up area .

Apartment at Bangalore : ARCOSYSS BUILDING: low rise framed structure : 10000 sft total built up area.

IT facility project in Bangalore: ARCOSYSS BUILDING 3000 sft : long span high bay structure

Apartment at Bangalore : ARCOSYSS BUILDING - low rise framed structure 30 feet clear span : 15000 SFT total built up area

PEENYA FACTORY : ARCOSYSS BUILDING - HIGH-BAY framed structure 40 feet clear span : 25000 SFT total built up area

Apartment at Bangalore : ARCOSYSS BUILDING – low rise framed structure 30 feet clear span : 5000 SFT total built up area

IT Facility at Bangalore : ARCOSYSS BUILDING – low rise framed structure 25 feet clear span : 10000 SFT total built up area

Apartment in Salem :–ARCOSYSS BUILDING - low rise framed structure 20000 SFT total built up area

250 SFT Mass Housing Demo at MYSORE : ARCOSYSS BUILDING Ground floor only

Construction of 10000 sft of School Building structure in Bangalore

10000 sft of IT Facility structure in Bangalore

10000 sft of Hospital Building structural extension

20000 sft of Industrial Building structure in Salem

20000 sft of Apartment Building structure

Construction of 15000 sft of Club House building structure in Bangalore

THE CE-MENTOR

The CE-Mentor is a trade name derived from The Civil Engineering Mentor.

This brand name represents A Resource Center for the Development & Promotion of Rapid & Alternative Building Construction Technologies such as FI-RCC Technology & CEMAC Technologies. Peer reviewed and backed by fundamental structural concepts these technologies have been successfully implemented/being implemented in various projects resulting in savings on many aspects such as time, cost, labor, equipment, energy, water, space and skill while concurrently adding value such as superiority in quality, safety, serviceability and scalability.

Vision: To be a resource center for the development & promotion of rapid & alternative building construction technologies.

The Promoter: Sebastian Gomes is the founder & the principal technologist of The CE-Mentor. He is a qualified practicing engineer having 36 years of professional experience. His core competence lies in Innovation, Design, Development, Consultancy and Construction.

After serving AFCONS & ISRO during the initial stages of his career, he has engaged himself in the research, innovation, development and implementation of several rapid & alternative building construction technologies in various projects.

Objectives & Activities:

- Research, innovation, development and demonstration of Rapid Construction Technologies

- Research, innovation, development and demonstration of Alternative Construction Technologies

- Consultancy & Construction management services to projects based on such technologies

- Technology assimilation and training programs to promote the implementation of such technologies

- Startup guidance and mentoring support to set up Micro-Business Ventures based on such technologies

- Manufacturing of ARCOSYSS & CEMAC technologies’ based Products for the Building Construction Industry

ARCOSYSS : CEMAC TECHNOLOGIES

CEMAC Technologies (The CE-Mentor Alternative Construction Technologies) are Innovative Technologies designed and developed by Sebastian Gomes to supplement/complement/substitute some conventional technologies without compromising the fundamental requirements such as strength, safety, serviceability, stability, durability and functionality; while simultaneously adding value and minimizing wastage. These attributes are achieved through a slew of measures such as technical innovations and value engineering. Some of the CEMAC Technologies developed and demonstrated in various projects are as listed below.

Plum Concrete Foundation for load bearing walls (G+2)

Stub Column Foundation for load bearing walls (G+2)

Maso-Crete I-Beam Foundation for load bearing walls (G+2)

Waffle slab foundation for load bearing walls in Black Cotton Soil (G+2)

Inverted flange beam foundation system for low-rise apartments (5 floors to 6 floors )

Micro-grid block wall system

Maso-Crete wall system

Laminated block wall system

Wood-Crete panel wall system

Sansucrete wall system

Partial pre-cast flange beam slab system

Jumbo LW filler block slab system

Sansucrete panel slab system

Partial pre-cast flange beam slab system

Sansucrete slab system

Wood-Crete panel slab system

Jumbo LW filler block slab system

FRP Formwork system

PLASTEEL Formwork system

CE-Mentor Ready SCC Mix can

CE-Mentor Ready LW Concrete Mix can

ARCO panel based Mass Housing system

Sansucrete based Mass Housing system

PLASTEEL based Mass Housing system

Composite Hand Crafted Door shutters

Shutter-less Ventilating windows

Wood-Crete Scantling Door frames

Secure & Detachable Window grills

Steel Rib /ARCO panel Bio-Clean KIT

Steel Rib /ARCO panel STP KIT

Steel Rib /ARCO panel Storm water drain KIT

Steel Rib /ARCO panel Manhole & silt trap KIT

Steel Rib /ARCO panel Water Closet KIT

Wood-Crete panel Flooring system

Low-Cost; Dust-proof Flooring System for industries

Steel RIB & Concrete Panel Compound Wall system

ARCO panel Compound Wall system

Steel RIB & Concrete Panel Liquid Storage system

ARCO panel Liquid Storage system

Maso-Crete Liquid storage system

Micro-grid Block Retaining Wall system

Stilted Residential Sites/Plots for Villas

ARCOSYSS : TAT & SGM PROGRAM

The CE-Mentor TAT & SGM program is a unique program designed to promote and foster Micro-Business Ventures based on various CEMAC Technologies. These programs are for enthusiastic engineers and aspiring entrepreneurs. The program module includes Technology Assimilation and Training backed by Startup Guidance and Mentoring support. One such typical program module is as detailed below.

The CE-Mentor TAT & SGM Program: CEMAC Technologies: Part-1: Foundation, Wall & Slab Systems

Technologies:

- Plum Concrete Foundation system for load bearing walls (G+2)

- Stub Column Foundation system for load bearing walls (G+2)

- Maso-Crete I-Beam Foundation system for load bearing walls (G+2) Waffle slab foundation system for load bearing walls in Black Cotton Soil (G+2)

- Inverted flange beam foundation system for low-rise apartments (5 floors to 6 floors )

- Micro-grid block wall system

- Maso-Crete wall system

- Laminated block wall system

- Wood-Crete panel wall system

- Sansucrete wall system

- Partial pre-cast flange beam slab system

- Wood-Crete panel slab system

- Jumbo LW filler block slab system

- Sansucrete panel slab system

Highlights:

- These are cost-effective alternative construction technologies

- These are stronger, reliable and efficient alternatives to conventional systems

- They can be implemented by using de-mystified and de-skilled construction procedure

- Most of these technologies can be adopted as Micro-Business ventures

Topics Covered:

- Technology Assimilation : Concept, Fundamentals, Advantages, Applications, Design Process

- Training : Construction Process, Demonstration, Hands-on training , Cost-estimation & Business Potential

- Startup Guidance and Mentoring support : Guidelines, Strategy & Mentoring support for Entrepreneurship

- Program Duration: 7 days: Includes Tutorials, Training, Practical Demonstration & Startup Guidance

Topics Covered:

- These are cost-effective alternative construction technologies

- These are stronger, reliable and efficient alternatives to conventional systems

- They can be implemented by using de-mystified and de-skilled construction procedure

- Most of these technologies can be adopted as Micro-Business ventures

Who should attend?

- Civil Engineers and Architects

- Contractors and Builders

- Aspiring Entrepreneurs

- Building Materials’ Manufacturers

Disclaimer:

This is neither a job offering nor a business proposition. This is a workshop where you will receive information, watch demonstration and get hands-on training pertaining to the implementation of some CEMAC technologies. You may consider adopting these technologies for your projects and also leverage the exposure/ knowledge gained to enhance your business prospects.

ARCOSYSS :

Voices of Our Clients

Discover the impact of our work through the words of our satisfied clients. Explore testimonials that speak volumes about our commitment to excellence.

The CE-Mentor team. Their guidance and support elevated our construction endeavors significantly.

BLD EZY

Mobile construction van for the effective, efficient, economical & eco-friendly execution of minor, miscellaneous & maintenance works.

Door-step service & hassle-free construction experience.

B acked by an App & a smart construction program.

Backed by multi-utility resource hubs.

Backed by alternative and rapid construction technologies.

ARCOSYSS Construction Technology - TESTIMONIALS

Mr. Girish Ramanathan – Entrepreneur & Businessman - Bangalore

Mr. Syed Ameen - Professional Structural Engineering Consultant - Bangalore

Mr.Siddharth Majumdar - Associate Director - Arcop Associates - Bangalore

Mr. Vignesh Gopalakrishnan - IT professional – Bangalore

Mr. Advith - Advith Architects - Bangalore

Mr. Dilip Narasimhan – IT professional – Salem

FAQ about ARCOSYSS Construction Technology

1. Is Arcosyss a new construction technology?

Not really. Arcosyss is actually a composite construction technology that combines the advantages of RCC , STEEL and PREFAB. In that sense, it's as old as these technologies. The Invention & innovation is all about the development of modelling, design and analysis methodology AND the various construction processes to combine the 3 technologies so as to get the best of ALL OF THEM.

2. Is Arcosyss a cost effective technology ?

In terms of cost of construction Arcosyss is definitely cheaper than PREFAB and STEEL. However, when compared to RCC ; it is on par ; but with multiple value additions at no extra cost (value additions: earthquake resilience, speed of construction, space optimization, overall sustainability and serviceability). In some cases such as high bay / long span structures Arcosyss may even work out cheaper than RCC.

3. Is Arcosyss a rapid construction technology?

Yes, it is. It's faster than RCC, STEEL and PREFAB due to simplification of form works , reinforcement works, fabrication works and reduction in lead time.

4. Is Arcosyss more durable than RCC & STEEL tech based construction?

Yes, it is. The use of galvanized steel, polymer modified concrete and polymer modified mortar makes Arcosyss Construction Technology based structures more durable.

5. Is Arcosyss a labour intensive technology?

No, it's not. Several skills required for shuttering works and reinforcement works have been removed from the construction processes and hence it's less labour intensive.

6. What benefits do I get if I opt for Arcosyss technology instead of RCC and STEEL?

You will get many advantages. Please peruse the technology comparison sheet .

7. Is Arcosyss a safe technology?

Yes, it is absolutely safe. Arcosyss is a composite construction technology that combines the advantages of RCC, STEEL and PREFAB. All these technologies are proven and time-tested.

8. Is Arcosyss a proven technology?

The modelling, design and analysis methodology pertaining to Arcosyss Construction Technology is peer reviewed by practicing structural engineers. We have also successfully implemented this technology to build more than 1 lakh sqft of buildings over the last 5 years.

9. Is Arcosyss a scientifically validated technology?

Yes, it is. The basic construction materials that are used to implement

Arcosyss construction

technology are time-tested

Cement, Aggregates, TMT Steel and GI steel.

The technical analysis and design of Arcosyss Construction Technology is based on

fundamental principles of proven RCC, STEEL and PREFAB technologies

which can be easily perused and reviewed by third-party qualified structural engineers; which is what we have done so far.

10. What certifications do you have ?

After successfully designing and building more than 1 lakh sqft of buildings based on this technology with valuable suggestions from third party structural engineers; we are now in the process of carrying out specific laboratory tests and further research in engineering colleges to make the technology more advanced, refined and versatile.

11. How can I rely on Arcosyss technology?

The explanation provided above vide 7/8/9/10 and also the testimonials shared in the PPT provide sufficient insights into the reliability aspects of this technology.

12. What guarantees do you provide and what's the defect liability obligation ?

We provide a 5 year defect liability guarantee for structural safety, stability and durability ; during which time noticeable defects if any shall be rectified by us free of cost.

13. Can you provide testimonials about Arcosyss Construction Technology?

We have shared a few testimonials in the PPT.

14. Can you provide test certificates pertaining to its structural strength, stability and durability?

As of now we can provide the design and analysis data pertaining to some of our completed projects at no cost. However, on project to project basis , exclusively, it can be provided by engaging a peer reviewer. There will be some costs involved.

15. Can we build highrise buildings by adopting Arcosyss Construction Technology?

Yes, we can build. Please note that Arcosyss Construction Technology is a combination of proven RCC , STEEL and PREFAB technologies.

16. How do you analyse and design Arcosyss based structures ?

The modelling, analysis & design of Arcosyss Construction Technology based buildings is done through well established and widely used software programs such as Etabs and Staad pro

17. Is Arcosyss fire resistant and corrosion resistant?

Yes, it is . In fact Arcosyss Construction Technology based structures exhibit better resistance to fire and corrosion as compared to conventional STEEL and PREFAB buildings

18. Can we build a small structure using Arcosyss Construction Technology?

Anything and everything can be built by adopting Arcosyss Construction Technology ; as it's the combination of proven RCC, STEEL and PREFAB technologies.

19. Are Arcosyss Construction Technology based buildings leak proof ?

Yes, they are. Arcosyss Construction Technology is the combination of proven RCC, STEEL and PREFAB technologies. The deficiencies pertaining to these conventional construction technologies have been addressed to completely solve / mitigate them.

20. What is the cost per SFT for buildings built by adopting Arcosyss Construction Technology ?

Cost per SFT is a relative subject. It depends on the structural configuration, site conditions, geography, soil type, total built up area, logistics etc. However the COST RANGE for FOUNDATION + STRUCTURE (including all walls and total plaster finish) may vary from INR 700 per SFT to INR 1000 per SFT of built up slab area. We will provide detailed cost break down for each project based on working drawings and detailed specifications.

Send Us A Message

Contact Info

Call Us

+91 861 840 0069

+91 938 101 3090

+91 740 649 3797

Our Email

arcosysstechnology@gmail.com

Our website

www.thecementor.com

Bangalore Office

#110, First floor, House of Lords, 15/16 St Marks Road, Bangalore– 560001

Chennai Office

The Workvilla, 'Kamala Arcade', Old # 669, New # 306, Anna Salai, Thousand Lights, Chennai - 600006

Manufacturing Franchise

Sansucrete Construction products LLP

Sy. No. 54/2, Dommasandra Village, Sarjapura Hobli, Bangalore Urban District, Bangalore - 562125